by monagraphic | Dec 15, 2017

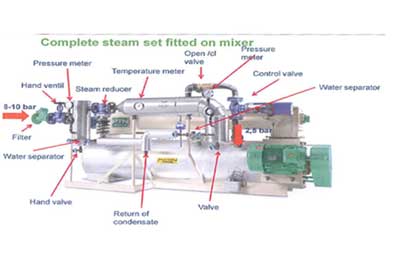

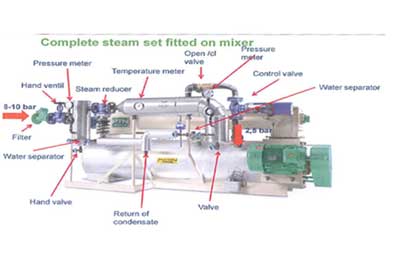

As part of a new build project, we can integrate the fluid part. We maintain a close relationship with the main players in the fluids market in the cereal industry sector. As such, we can support you to best size your equipment and comply with your RFP specifications,...

by monagraphic | Dec 15, 2017

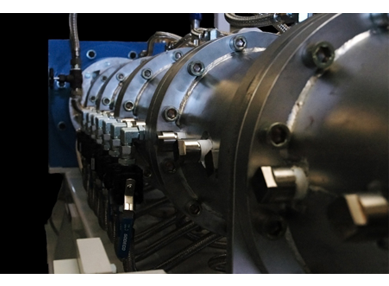

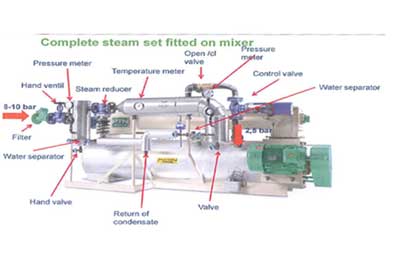

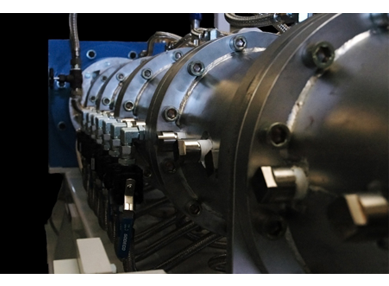

We can supply you with all of the equipment required for an extrusion line : – Dosage, Crushing, Drying, Cooling – For the extrusion part, we work with recognised manufacturers in the cereal industry and we can bring you our experience as an integrator....

by monagraphic | Dec 15, 2017

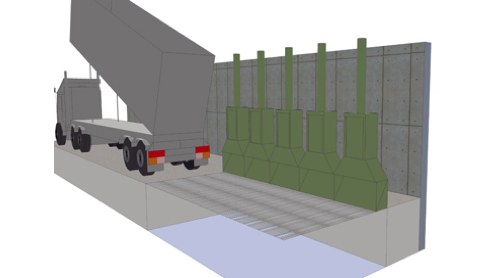

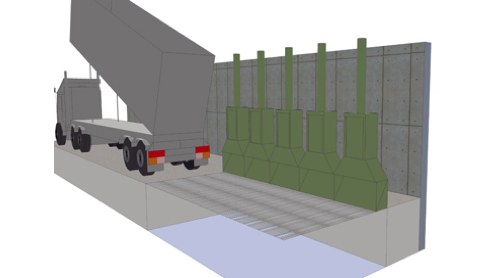

– We make receiver pits for receiver circuits with a capacity of 25 to over 300 tons per hour. – This pit can be installed above or below ground, depending on the desired capacity level and the customer’s preferences. – We can integrate high...

by monagraphic | Dec 15, 2017

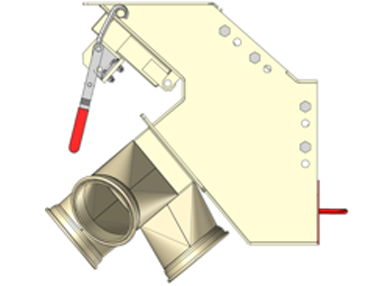

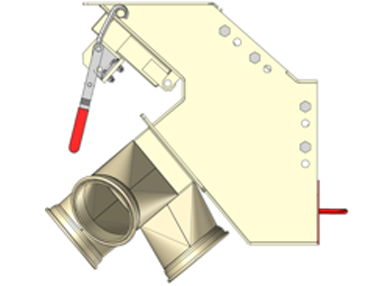

– Our magnetic stone remover is designed to eliminate stones and metal parts that may be found in raw materials prior to crushing. – The magnetic stone remover is an essential crusher safety component as it protects crusher grilles from being perforated by...

by monagraphic | Dec 15, 2017

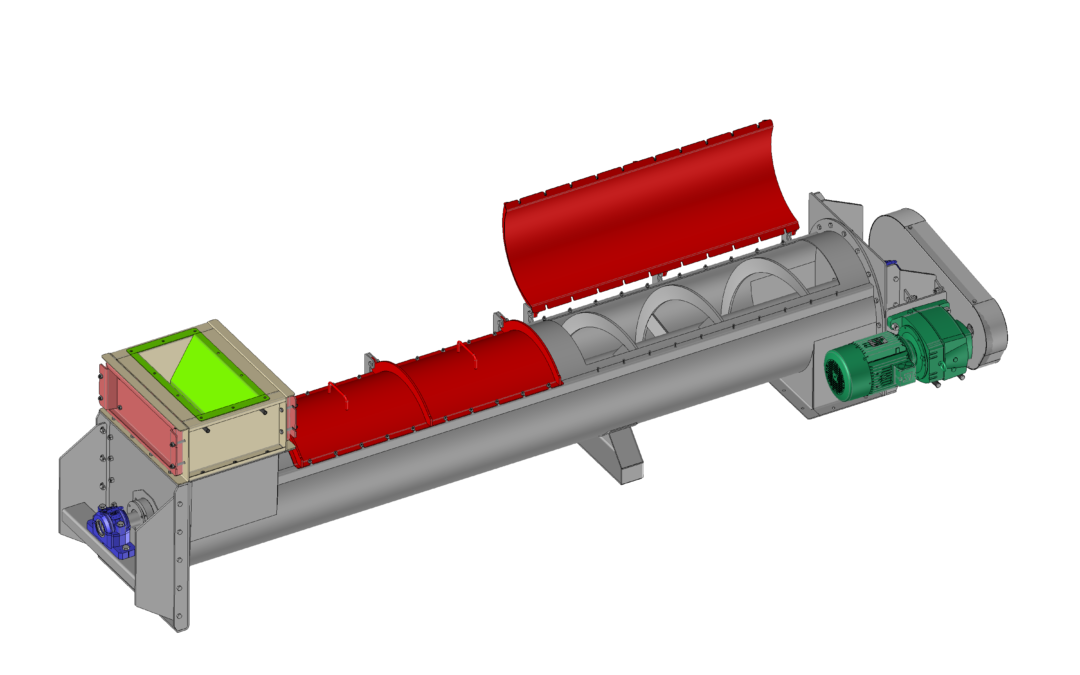

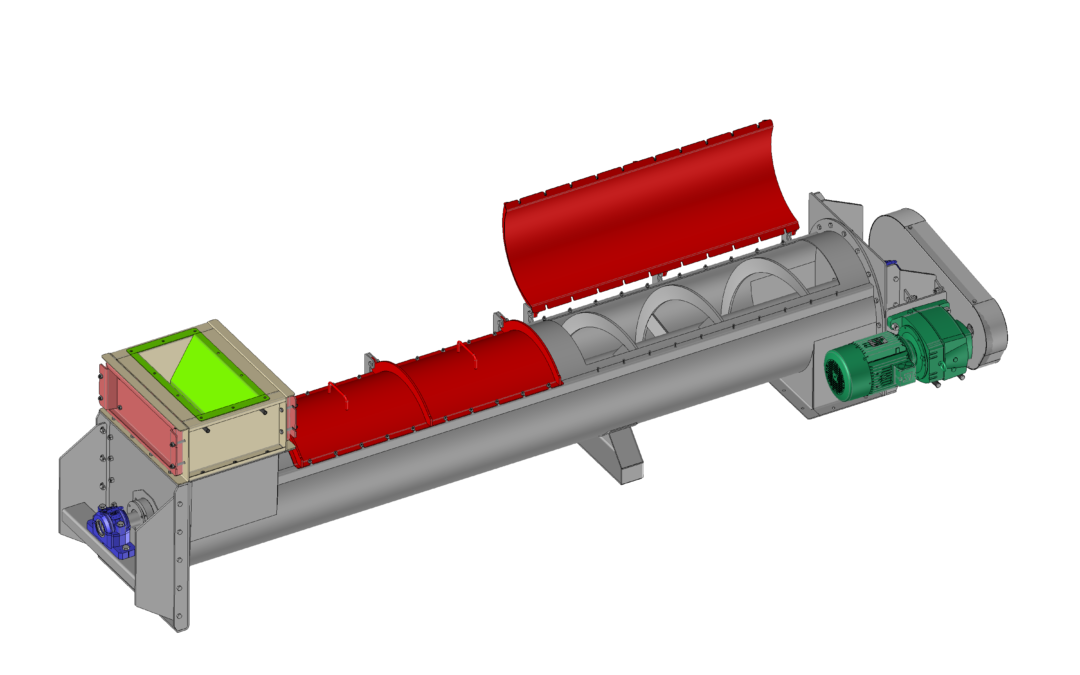

This equipment is used to coat granulose products with a liquid material (1 to 8% liquid content). – Diameter: 400 to 500mm. – Flow rate: 5 to 60 tons per hour. – One or two 4 nozzle sprayers for each coating box and two boxes may be superimposed....